Great Support for Automotive Manufacturing

Through the support of the SLM Solutions there are manufactured specific components with the SLM® process. Because of undercuts, radii or hollow chambers, these components can´t be manufactured by conventional methods. By the SLM process, the calipers and wheel were optimized. The caliper needs only a connection to the brake  circuit, resulting in better distribution of brake pressure being built on the four existing brake piston. Furthermore, the venting of the circuit is greatly facilitated by the special shape.

circuit, resulting in better distribution of brake pressure being built on the four existing brake piston. Furthermore, the venting of the circuit is greatly facilitated by the special shape.

The wheel carrier is due to cavities very easily. It was estimated only in the field of material forces to give very short and direct force paths. In addition, the wheel was designed so that the initiation of the steering forces makes no additional screws necessary.

Let’s see Blade, the world’s first 3D-printed production supercar, was printed by the world’s fastest 3D metal printer from SLM Solutions:

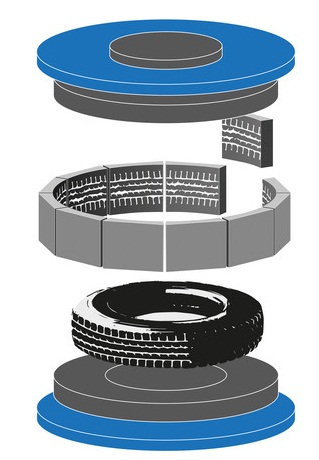

Tire mould segments manufacturing by SLM-Technology

Fast, accurate and inexpensive tire mould production.

SLM Solutions is proud to “drive & lead” the tire world in a new generation, by using the SLM® technology for tire moulds.

The Selective Laser Melting technology (SLM) enables the production of new tire tread mould segments in shorter time, less expensive and using three-dimensional geometries for prototype and mass production tools.

Melting technology (SLM) enables the production of new tire tread mould segments in shorter time, less expensive and using three-dimensional geometries for prototype and mass production tools.

Due to the layer by layer process using fine metal powder which is melted with a 400 W or 1000 W laser or with our multi laser technology up to 4x 400 W in the SLM 500, the SLM® technology allow tire makers to create new, more intricate tread designs with fine small gaps or even three-dimensional and internal undercut structure design for the next generation of tire profiles. With the quad laser technology 4x 400 W in combination with our patented bi-directional recoating system, SLM Solutions increases the build-up rate up to 90% compared with the twin configuration (2x 400 W).

Tire manufacturers are turning to the SLM 280 or SLM 500 machine series to balance improved traction on wet surfaces versus stability on dry surfaces with optimized slits on a tire tread, known as tire blades